KnowledgeECONOMICS

CONTACT US

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »Vertical Sump Pump

Structure description of multi-sucker corrosion-resistant submerged sewage pump

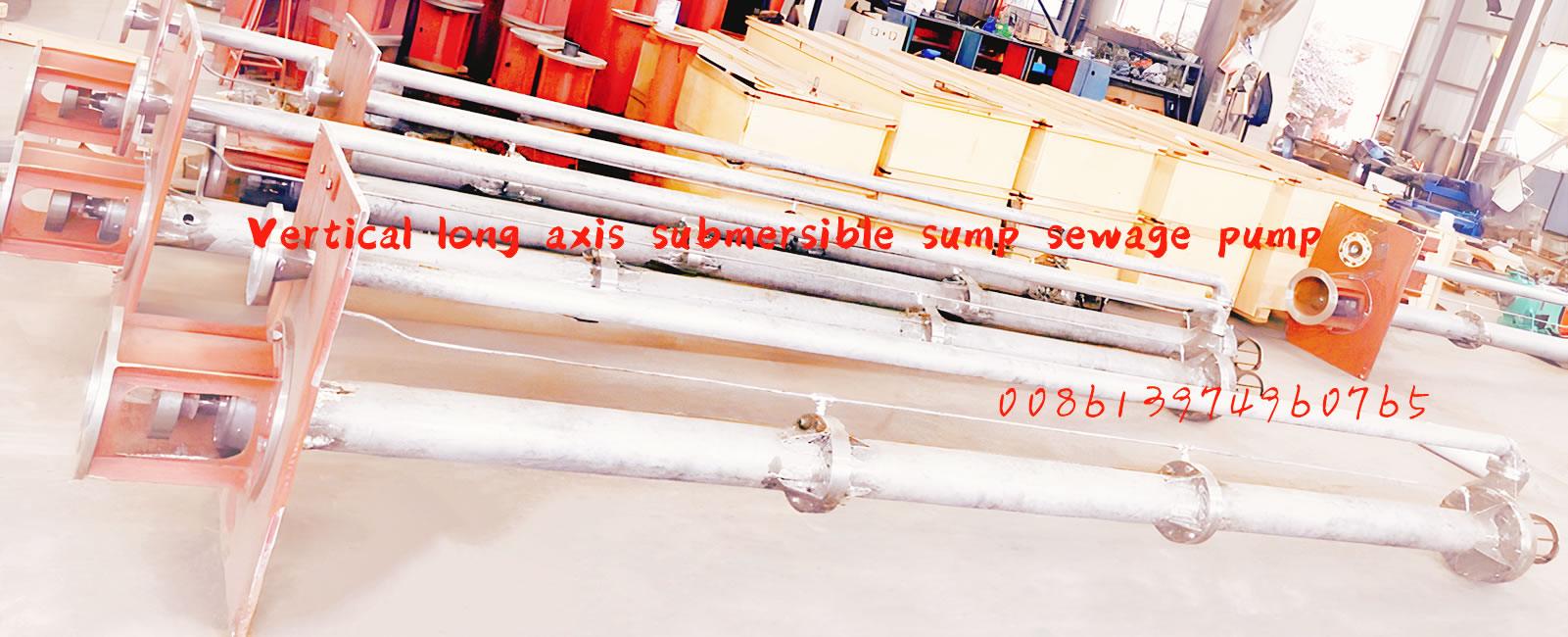

PWDL multi-suction corrosion-resistant sewage pump is mainly composed of pump body, pump cover, impeller, shaft, sealing ring, elastic coupling, bearing body parts, sliding guide bearing, skeleton oil seal, connecting pipe, outlet pipe, bottom plate, motor support and other parts.

The suction port of the pump follows the axis direction, and the outlet is parallel to the axis.

The steering of the pump is seen from the suction port to the motor end and rotates counter-clockwise.

The vertical motor of PWDL multi-sucker corrosion-resistant submerged sewage pump is fastened to the motor support by bolts and drives directly with the pump through elastic coupling. The pump body, multi-sucker base, connecting pipe, bearing body parts and outlet pipe are connected by bolts and fixed on the bottom plate. The whole pump is installed on the container through the bottom plate. PWDL multi-sucker corrosion-resistant submerged sewage pump is made of cast iron or common carbon steel except for liquid-contacting parts, such as motor support, bearing body related parts, bottom plate, etc.

The axial and radial forces (including water pressure, impeller and rotor weight, etc.) of the pump are borne by deep groove ball bearings, self-aligning ball bearings and sliding guide bearings installed in the bearing box. In order to ensure the safe and normal operation of the pump, the upper rolling bearings of the bearing body components are deep groove ball bearings. SKF self-lubricating rolling bearings are used, and no additional grease is needed during the life of the bearings. Lower rolling bearings adopt self-aligning ball bearings, lubricated with No. 3 lithium grease, which need to be added or replaced regularly according to the use. Sliding guide bearings are lubricated by the transported liquid. The shaft seal adopts two skeleton oil seals as the basic sealing form, which mainly prevents foreign bodies from entering the sliding guide bearings outside the pump. It also prevents excessive leakage of medium in the pump.

In order to ensure the normal operation of the pump, the liquid level must be higher than the impeller center line.